Introducing the Autobag® AB 180™ — Setting the pace in packaging technology. Capable of bagging at speeds up to 80 bags per minute, this automatic filling and sealing machine has been designed to be simple to use, dependable and operationally flexible to give maximum machine uptime and packaging productivity. Package size changes can be achieved in less than 2 minutes using Autobag Bag-on-a-roll pre-formed bags. Utilizing the very latest technology, Autobag Replace-n-Repair™ machine operating systems and the most advanced user touchscreen available, the AB 180 is the most reliable, and the easiest to use automatic bagging system available. The large interactive AutoTouch™ Control Screen allows operators to quickly recall and set-up packing jobs. The system’s high capacity memory makes multiple job storage easy, and the touchscreen offers a powerful diagnostic help tool to enable operators to rectify machine errors quickly and easily. Using Autobag Bag-on-a-roll polyethylene bags, the AB 180 offers a fast and cost-effective packaging solution. User Benefits • Quick to set-up, easy to operate, reliable and fast • Change bag size easily in less than 2 minutes for maximum machine uptime • Powered Unwind provides positive web control for maximum cycle speed and accurate loading • Operator friendly AutoTouch™ Control Screen for easy job set-up and control • Built in diagnostics and help screens for rapid problem solving • Replace-n-Repair™ system for vital components to ensure minimum downtime due to machine failure • Combine with Autobag thermal imprinters for complete Print-n-Pack™ in-line product identification and labeling • Can tie-in to a range of Autobag and third-party infeed equipment

Open the catalog to page 1The Autobag PaceSetter PS 125 and PS 125 OneStep tabletop automatic baggers efficiently bag and seal your products. These hand load machines bring simplicity, versatility, and value to your low-to-mid volume production environment.

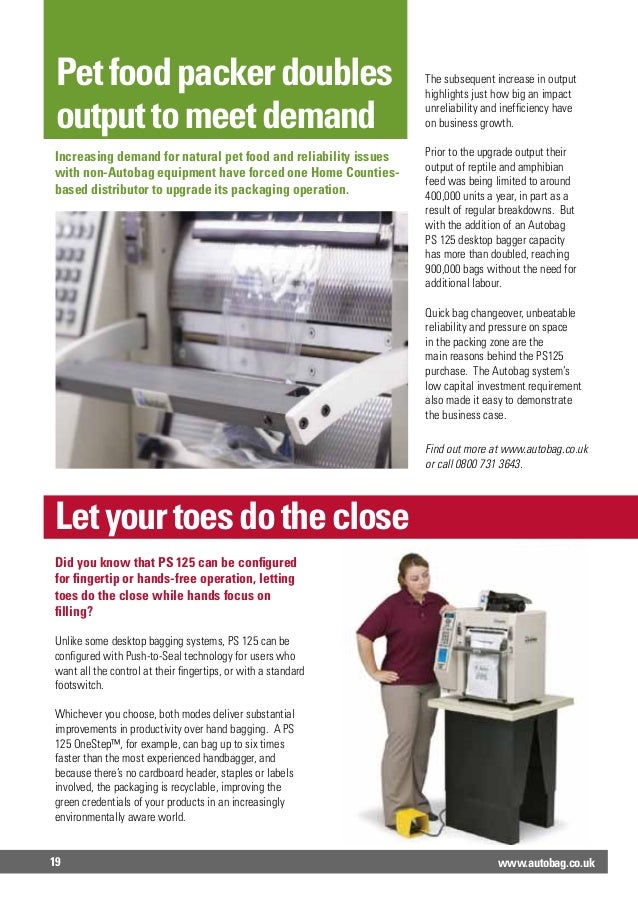

Operating at speeds up to 25 bags per minute (15 BPM OneStep version), these machines offer innovative engineering in a straightforward, tabletop design. The PS 125 features a small footprint of 22 x 19 inches and weighs just 82 pounds. The quiet, all-electric design does not require compressed air to run.

Search through 3.000.000 manuals online & and download pdf manuals. The Autobag ® PaceSetter PS 125 ™ and PS 125 OneStep™ Tabletop Baggers are specifically designed to bring simplicity, versatility, quality and value to hand load packaging applications. Operating at speeds up to 25 bags per minute (15 BPM OneStep version), the PS 125 bagging systems offer innovative engineering in a simple, tabletop design. The Autobag PS 125 is simple to operate, with a user-friendly display that enables easy access to operating parameters, job set-up, job storage, and on-board system diagnostics. The unique, locking turntable links with the AutoThread™ feature to provide ergonomic handling and bag changeover.

The Autobag PS 125 is simple to operate, with a user-friendly display that enables easy access to operating parameters, job set-up, job storage, and on-board system diagnostics. The unique, locking turntable links with the AutoThread feature to provide ergonomic handling and bag changeover. Polybags are automatically indexed, loaded by hand, then sealed using the Push-to-Seal automated sealer function, a standard footswitch, or automatic cycle control.

If you've misplaced the Owner's Manual that came with your system, we can help! Simply fill out the form below and a representative will contact you regarding your particular equipment. Do note, replacement Owner's Manuals are available for a fee.

The PaceSetter PS 125 OneStep includes the same conveniences as the standard PS 125, except with a built-in PI 412 Imprinter. It features next-bag-out printing technology that is ideal for short-run, order fulfillment and e-commerce applications such as pharmacy or catalog orders. High-resolution graphics, text, and bar codes can be printed on the bag, eliminating the need for a separate labeling operation. The printer features a tilt-back print head for easy maintenance, and the optional AutoLabel Design Software simplifies label creation.

System-matched Autobag pre-opened Bags-On-A-Roll are conveniently available in sizes 10.5″ wide and 17″ long. Pairing these systems and polybags offers an exceptional packaging solution for your hand load applications.

Autobag PaceSetter PS 125 and PS 125 OneStep Machines Fast Facts

User Benefits:

- The all-electric system does not require compressed air to run

- Compact design is ideal for low- to mid-volume packaging operations

- Locking turntable and AutoThread feature provide easy bag access and changeover

- Open loading area and controlled seal bar maximize loading flexibility and operator safety

- Automatic or manual operating modes for optimum flexibility and productivity

- Stores jobs for later recall using operator-friendly controls

- On-board system diagnostics simplify maintenance and maximize productivity

- The next-bag-out printing feature ensures greater accuracy and eliminates product queuing in order fulfillment applications*

- Capable of printing high-resolution graphics, text, and bar codes directly on the bag*

- Tilt-back printer head for easy maintenance*

* — PS 125 OneStep version only

Typical Applications:

- Automotive & Appliance parts

- Hardware & DIY

- Electrical & Electronic

- Plumbing & Heating

- Hobby & Craft

- Product Fulfillment

- Jewelry & Novelty Items

- Cosmetics & Beauty Aids

- Disposable Health Care

- Mail Order Fulfillment

- Ecommerce Fulfillment

Technical Specs

Weight: PS 125: 82 lbs. (37 kg); PS 125: OneStep – 110 lbs. (50 kg)

Electrical: 110/220 VAC switchable; 50/60 Hz; 5.0/2.0 Amps

Dimensions:

- Length: 19″ (48 cm)

- Width: 22″ (56 cm)

- Height:PS 125: 22″ (56 cm); PS 125: OneStep – 26″ (66cm)

Pass-Through: Up to 3.4 in.

Autobag Ps 125 Troubleshooting

Bag Thickness: 1.0 to 4.0 mil

Bag Sizes:

Autobag Ps 125 User Manual

- Length: 4″ – 17″

- Width: 2″ – 10.5″